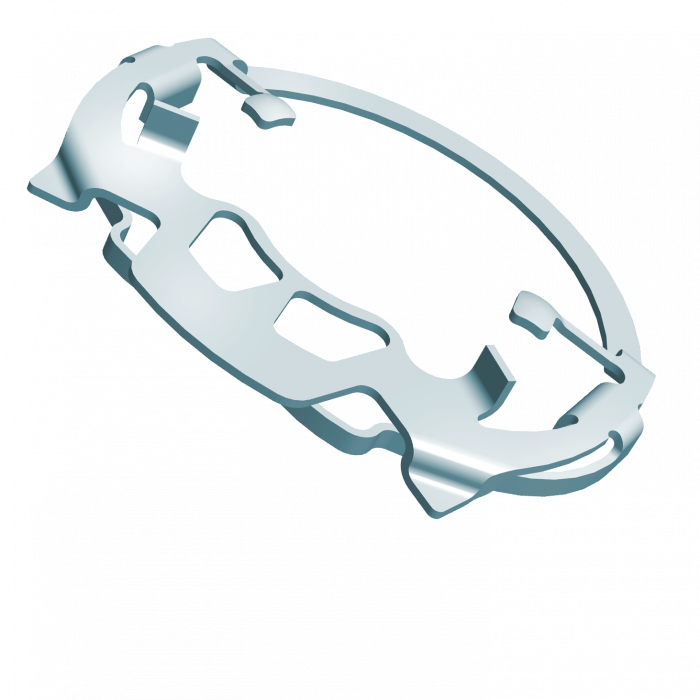

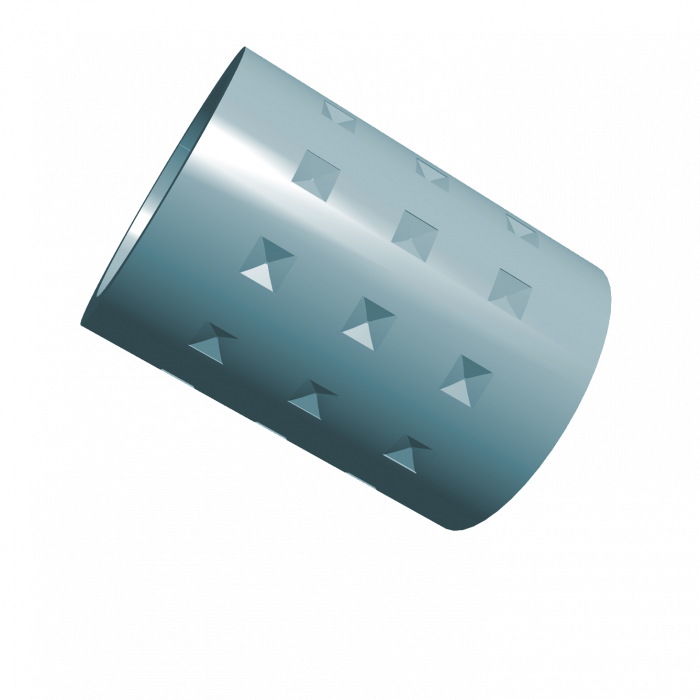

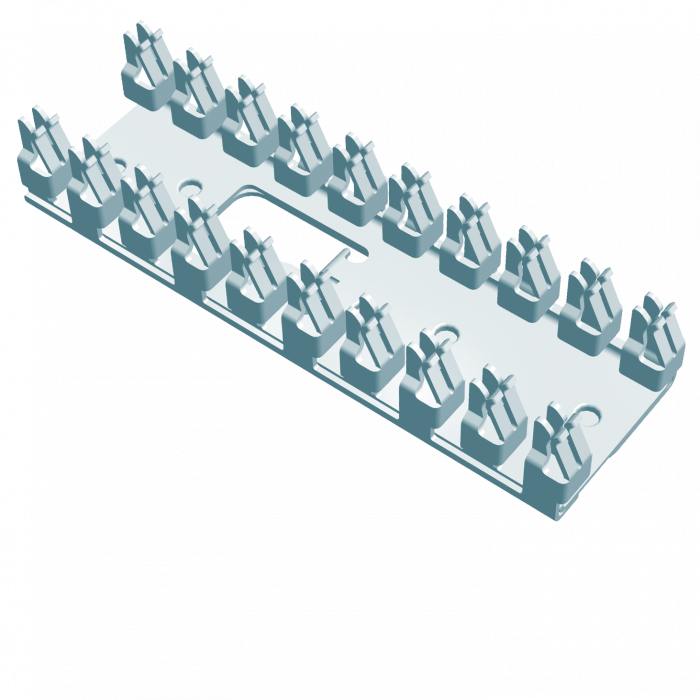

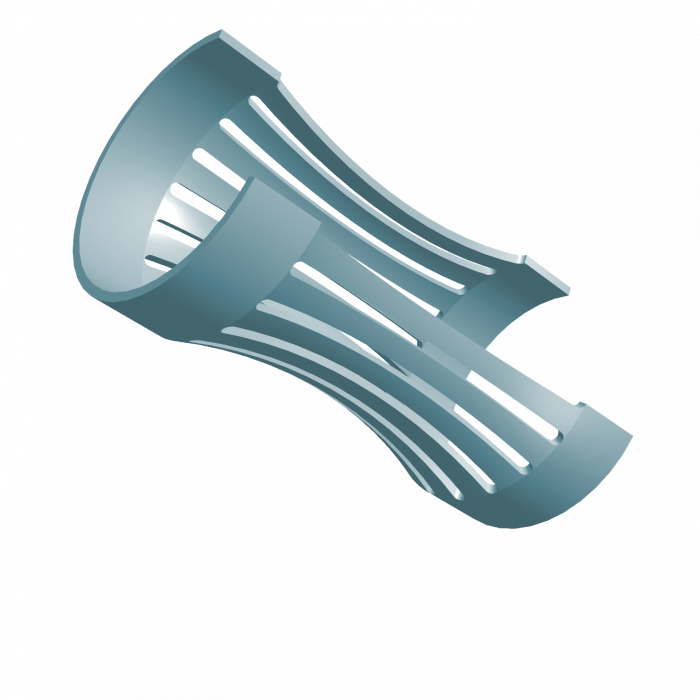

Stampings and Bendings

customized stampings and bendings

Our in-house tool development activities and toolshop enable us to offer optimized and customer-specific stampings in a range of materials. Our expertise encompasses stainless steels, spring steel strip, pre-coated or pre-hardened material and non-ferrous metals. Our entire stampings expertise worldwide is concentrated in a single business division. So we can handle global projects efficiently and share knowledge across continents